If you work with UV inkjet printing, you have likely heard the industry talking about “TPO-free” inks. But what is TPO, why is it being discussed, and do you need to change anything? This guide breaks it down in simple terms.

What is TPO and why is it used in inkjet inks?

Trimethylbenzoyl diphenylphosphine oxide (TPO) is a photoinitiator used in UV-curable inkjet inks. Its primary function is to absorb UV light and trigger a polymerization process to cure the ink. TPO has been used widely for years, across many industries to create high performance, cost-effective UV curing products.

Why are we hearing about TPO-free inks?

In June 2023, the European Chemicals Agency officially listed TPO as an SVHC (Substance of Very High Concern) under the REACH regulation, due to concerns over its potential reproductive toxicity. This means that in the EU and UK, TPO use has additional regulatory requirements, particularly that products must now carry more severe hazard warnings that may affect customer perception.

In the EU and UK, TPO has been reclassified to include a higher category of toxicity to reproduction (category 1B, H360Fd) than it previously was. This will have to be stated on labels and safety data sheets. There is currently a transition period for companies to make these changes, and the final compliance deadline is 20 April 2025 for the UK, and 1 September 2025 for EU. Currently these regulations do not apply to countries outside of the EU and UK.

Additionally, the European Printing Ink Association* (EuPIA) already includes TPO on its exclusion list, meaning it is not recommended for use in printing inks where there is a significant risk of human exposure. So, if OEMs want to supply EuPIA-compliant inks, TPO cannot be part of the formulation.

Because of these factors, many ink manufacturers are developing TPO-free alternatives, and some customers are actively requesting them. However, this does not mean all inkjet print systems need to be switched.

Impact of the TPO reclassification

TPO can still generally be used in ink formulations, but with the new regulatory requirements. For ink formulations containing more than 0.1% TPO, the main requirements are:

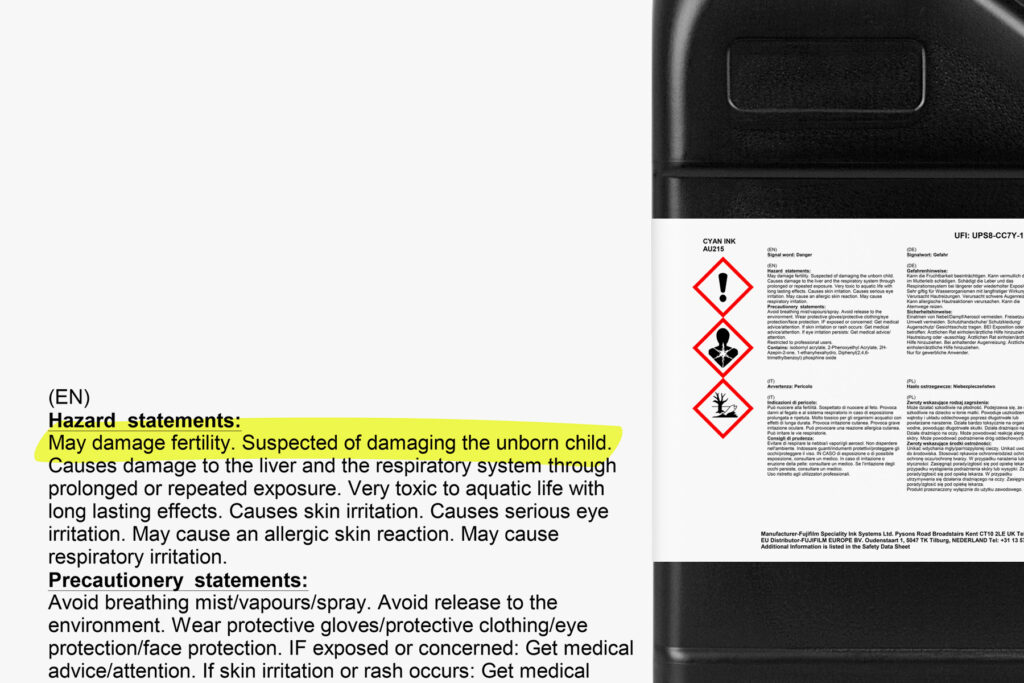

- Hazard labelling: Inks containing TPO require additional hazard warnings on safety data sheets and product packaging, including the phrase “H360Fd: May damage fertility. May damage the unborn child.”

- Safety data sheets: Substances must be listed as an SVHC on safety data sheets.

What else is there to know about TPO?

With regulatory changes, there is often uncertainty about what they really mean. Here are some key things to know about TPO and the latest reclassification:

- TPO-free inks are not mandatory – While some customers may prefer them, there is currently no legal requirement to remove TPO from ink formulations in most applications.

- Before its reclassification, TPO was already not allowed for use in food packaging inks by Swiss Ordinance and Nestlé.

- TPO-free inks do not automatically mean “safer” – While TPO has been classified as an SVHC, alternative formulations should always be evaluated for health and environmental impacts.

- Reformulating a product takes time and investment – Simply replacing TPO with a different photoinitiator may not be possible, and reformulation is required to achieve the same performance and robustness.

- TPO-free inks can cost more – New formulations require research, testing, and sometimes more costly raw materials.

Which printing sectors are affected?

The most affected sectors are those where UV-curable inks are commonly used and where regulatory compliance is a key concern.

UV packaging: Packaging and labels often involve food, beverage, and pharmaceutical products, where regulatory compliance is strict. Food contact regulations prohibit use of TPO in food-contact and indirect food contact inks, so printers usually prefer TPO-free.

Sign & display printing: Many large-format UV prints are used for corporate branding, retail, and outdoor signage, where sustainability and safe printing are becoming priorities. Some corporate clients request TPO-free inks as part of their environmental policies.

Fujifilm’s approach to TPO in inks

At Fujifilm Ink Solutions Group, we understand that different customers have different needs right now. That’s why we currently offer both TPO-containing and TPO-free inks:

- Existing formulations with TPO: These remain available for customers who want to maintain existing product performance and robustness in applications that are less sensitive to the new hazard labelling.

- TPO-free formulations: Fujifilm is actively formulating inks without TPO for customers who prefer alternatives, especially in response to the reclassification.

Future possible changes to regulation

This is the current status of TPO, as of early March 2025, but there is always potential for future change to the chemical regulations. In addition, although these regulations are set by the EU and UK, they are often adopted by brands, or industries sensitive to product safety, as their global standard. Through its expert teams, Fujifilm continuously monitors its regulatory position and updates products to ensure customers remain compliant.

*What is the EuPIA Exclusion List?

The EuPIA Exclusion List is a set of guidelines published by the European Printing Ink Association (EuPIA) that identifies substances not recommended for use in printing inks. The list is widely respected within the industry as a best practice standard for ensuring consumer safety and regulatory compliance. Ink formulators rely on the EuPIA list to develop products that align with brand owner expectations, food contact regulations, and market demands.

Useful links

ECHA SVHC list

EuPIA Exclusion List

Learn more about Fujifilm inkjet inks

Learn more about TPO-free label inks

Contact us if you would like a pdf version of this article